Revolutionizing Product Data Management: A Guide to a Successful ETIM Integration

Efficient product data management is a very demanding process. From the complex details of product specifications to various domain-specific words. Moreover, the lack of a common language between different parts of the company often leads to misinterpretations. Resulting in costly errors, delayed decision-making, and missed opportunities.

In our last article, we explored how you gain control over your product data with PIM. Now, let’s take the next step and see how the Electro-Technical Information Model (ETIM) can push your business to new heights.

# What is ETIM?

ETIM stands for Electro-Technical Information Model, and It is a classification standard. It is designed to create a universal language for product information across industries. ETIM achieves that by structuring product data into a two-level taxonomy. It allows products to be categorized, organized, and communicated consistently in a standardized manner.

Picture ETIM as a digital encyclopedia for technical products. It assigns each product a specific place within a well-organized framework. It ensures that everyone speaks the same language when describing products' details. Those can consist of attributes, specifications, and functionalities. This not only eliminates confusion arising from varied terminology but it also transforms how businesses manage their data.

ETIM ensures accurate info for all, from makers to users in any tech industry. Besides electrotechnical products, ETIM now also covers the classification of other industries. This includes HVAC & plumbing, building materials, shipbuilding sector-related products, and tools.

# About the ETIM International

ETIM International serves as a guardian of the ETIM classification model. They are a nonprofit organization whose main mission is the global adoption of the ETIM standard. To do so, they support a collaboration between different industries. This collaboration includes manufacturers, distributors, and more.

ETIM was initially developed for the Dutch electrotechnical sector. But later expanded its activities to different industries and countries worldwide.

At the local level, individual countries often establish their own ETIM organizations. These local entities tailor the global ETIM framework to suit regional industry nuances. They take care of things like linguistic preferences and specific product ranges.

These organizations work with local companies to drive the adoption of ETIM. Local organizations bridge the gap between global standards and local requirements. This helps achieve smoother communication and collaboration within their specific markets.

ETIM has been adopted in 20 countries, including much of Europe, North America, and Australia

Some of the biggest manufacturers are using the ETIM standard, including:

- Grundfos

- Sonepar

- SIEMENS

- 3M

- ABB

- OSRAM

# ETIM releases

ETIM is an open standard available to all, free of charge. Official international ETIM releases take place about every three years.

To meet the market’s wish for a more flexible standard, they also offer so-called "dynamic" releases. A dynamic ETIM release contains all classes that are already published. However, they are extended by classes with the status 'ready to state.' The classes are marked with change codes to state the differences from the current official ETIM release.

The dynamic release offers significant advantages but might result in challenges. It’s up to the individual local ETIM organizations to use it.

# The structure of ETIM

Understanding the ETIM model can be your first step toward a more structured approach to data in your business.

The ETIM model is a two-level classification model. The two levels relate to product groups and product classes. Each product class is assigned to one single product group. This enables a clear relationship between different categories and subcategories.

Group and Class: ETIM starts with broad categories encompassing general product groups. Those groups can be such as "Switches" or "Cables." These groups are then divided into more specific classes. For instance, under "Switches," you might have a class like "Light Switches".

Features: ETIM defines a set of features relevant to each group and class. These attributes provide detailed information about the products. The information ranges from technical specifications to features and dimensions. The feature includes a description, feature type, unit, and/or value.

Values: Each alphanumeric feature of an ETIM class has a list of possible values.

Unit: Numerical and range features always need a unit of measurement. An exception is features like “number of…”. These numerical features do not need a unit.

# Real-life example

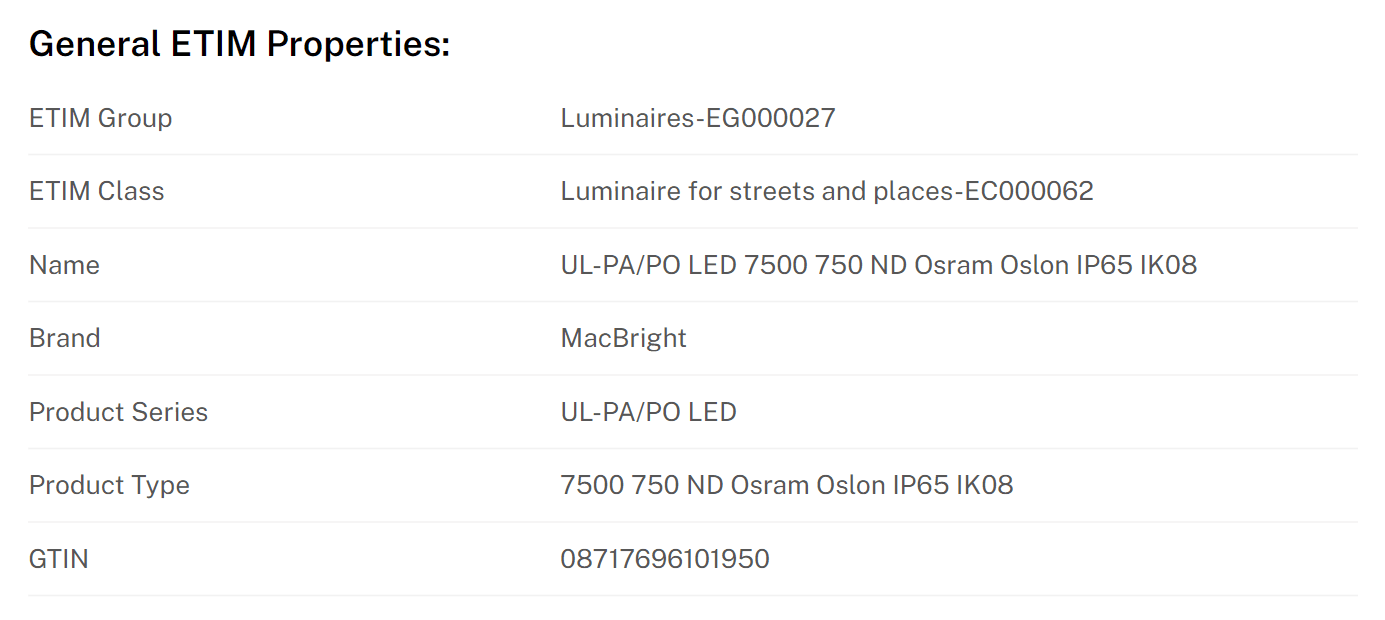

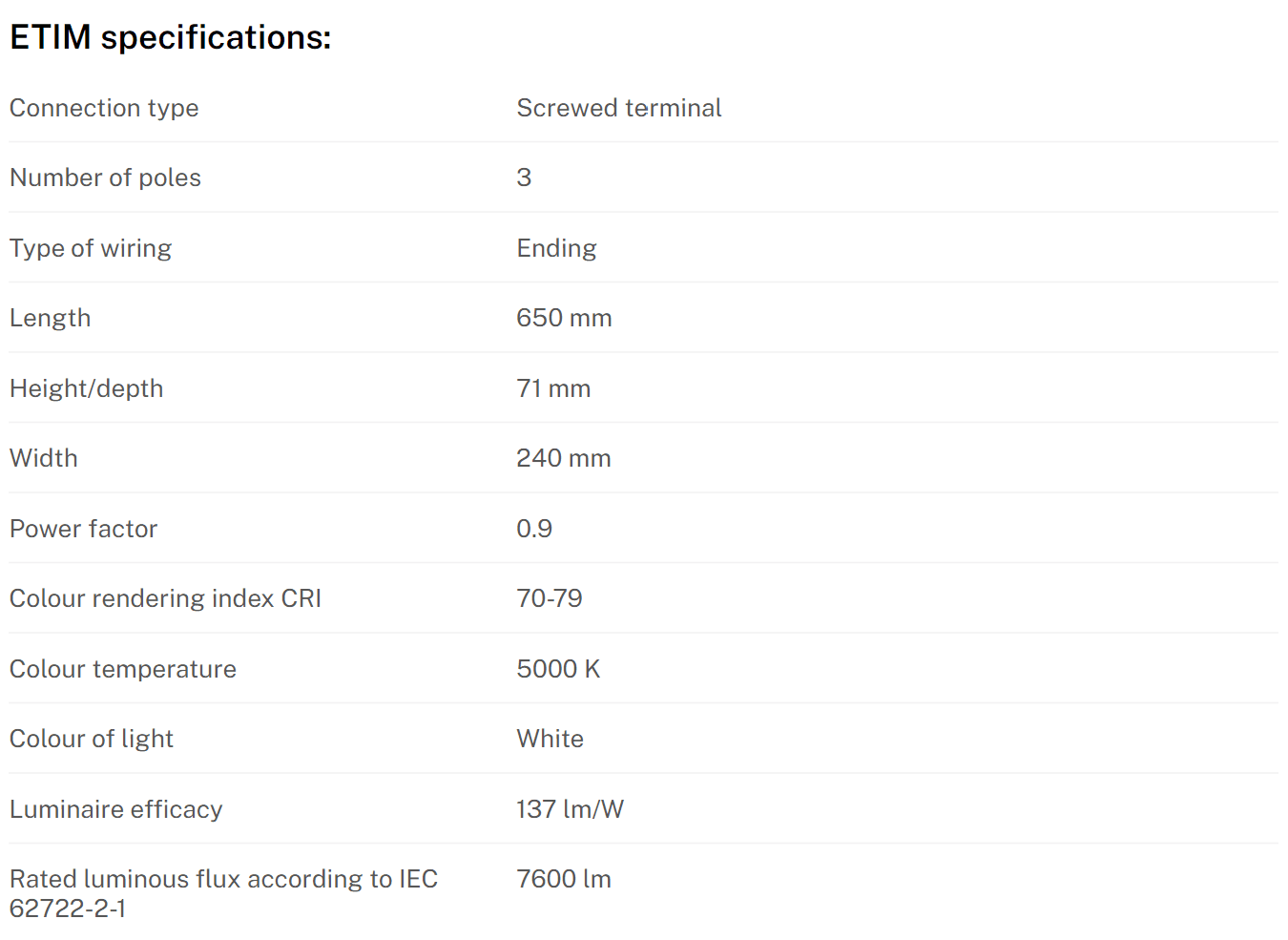

Let's look at a real-life example to better understand how ETIM works. Below you can find an ETIM description of a smart lightning solution. As you can see, the product has a class EG000027 (Luminaires), which serves as a 'main category'. The information is followed by ETIM class EC000062 (Luminaire for streets and places), which serves a product subcategory.

Below the general ETIM properties, you can find more detailed information. All those properties are specified by ETIM classes. With predefined properties like this, comparing different products that share the same ETIM class is way easier.

Without ETIM classes, a product description might look something like this:

The Mac Bright UL PA/PO LED 7500 750 ND Osram Oslon IP65 IK08 is a durable and energy-efficient luminaire from the UL-PA/PO LED series. It features a power factor of 0.9, luminaire efficacy of 137 lm/W, and produces a luminous flux of 7600 lm with a system power of 56 W. The light has a color temperature of 5000 K, a CRI of 70-79, and is distributed through a focal lens.

The LED lamp has a rated life of L90/B10 at 25°C for 30000 hours, L80/B10 at 25°C for 50000 hours, and L70/B50 at 25°C for 100000 hours. The luminaire has a protection class of I, an impact strength of IK08, and a degree of protection of IP65. It has an aluminum housing with a grey powder coating and a transparent glass cover. The luminaire has a screwed terminal connection, 3 poles, ending type wiring, and is suitable for spigot size 42 mm. It can be mounted via post top or side entry and has a constant light output (CLO).

It does not include a connection cable, light regulation program control, radio control, remote control, adjustable optics, or dim function. It includes a current-controlled LED operating device and operates at a nominal voltage of 220 V (AC).

Which version do you like better?

# How ETIM can benefit your business

Using ETIM brings many benefits for companies dealing with technical product data. Some key advantages include:

# Better data quality

ETIM's standardized structure minimizes errors in product data. It is achieved by providing a uniform format for attributes, specifications, and descriptions. Coupled with its two-level structure, ETIM provides consistent data organization. Products are categorized into product groups and classes. This organized approach streamlines processes such as inventory management and product searches.

# Easier communication

ETIM establishes a common language for technical product information. With that, it helps end confusion arising from diverse industry jargon. This consistent terminology ensures that all people involved understand the product data in the same way.

Using standardized terminology, ETIM enhances communication between manufacturers, distributors, suppliers, and customers. This streamlined communication accelerates decision-making and fosters collaboration across the supply chain.

ETIM fosters collaboration among B2B partners. Manufacturers and distributors can easily exchange accurate and detailed product data. This leads to smoother transactions, fewer disputes, and enhanced business relationships.

# Faster adaptability

ETIM's adaptable structure accommodates new products and industry changes. As technologies evolve, businesses can seamlessly integrate novel products into the existing framework. This ensures their data management practices remain up-to-date.

Beyond its immediate advantages, ETIM lays a robust foundation for digital transformation initiatives. It supports the integration of advanced technologies like AI and automation. With the possibility to incorporate new technologies into your business, you will never stay behind.

Additionally, ETIM's standardized approach helps companies meet industry regulations and compliance requirements. Accurate and consistent product data aids in adhering to standards and guidelines. As a result, we can reduce the risk of legal and regulatory issues.

# Time and cost savings

The use of ETIM cuts errors and enhances collaboration. ETIM contributes to overall time and cost savings across various operations. Resources spent on correcting mistakes can now be directed toward value-added activities.

# How to implement ETIM in your organization

Deciding to integrate ETIM into your company is a smart move. But before you step into it, you should be well prepared. Implementing ETIM without the proper preparations might result in crushing failure.

ETIM is more than data. It's a transformative approach to making technical product information understandable. With a correct strategy, your team knows their role, the goals, and how to dodge potential pitfalls. This clarity ensures the tech doesn't fit but integrates with your current systems.

But without that guiding plan, you risk wandering off course. ETIM's full potential is vast, but to unlock it, a well-charted roadmap is essential. Here’s how you should approach an ETIM implementation in your company.

1. Introduction to ETIM

Understanding the foundations of ETIM is pivotal. At its core, ETIM is a classification model for technical products. It focuses on the electro-technical sector. Grasping its role in different areas will ensure consistency in product classification.

2. Assessment & Planning

Create a plan. Before diving in, a comprehensive audit of current data practices is necessary. This means looking for problems in different sets of data. Other steps that you need to consider are how and where you will store the data. This can set the stage for a smoother integration of ETIM into existing processes.

3. Training & Awareness

Knowledge is the key to successful adoption. Organizing specialized ETIM workshops will help in familiarizing stakeholders with the model. To empower a broader organizational conviction, it's essential to highlight ETIM's benefits.

4. Implementation

Turning knowledge into action requires the right tools and a detailed approach. This is the most crucial part of the whole planning process. Thiswill be a place where most of the challenges will arise. The implementation should be done by introducing small incremental changes. The changes should then be measured by defined scopes in planning sessions. It is also important for your company to invest in PIM systems matched to ETIM standards. The migration of existing product data into the new system must be undertaken to ensure accuracy and consistency.

5. Integration with Partners

ETIM's potential is amplified when extended to the entire supply chain. By onboarding suppliers and educating customers, companies can ensure seamless data interchange. This collaborative approach can create a way for standardized communication with other companies.

6. Continuous Improvement

Adoption is just the beginning; refining the process is ongoing. Feedback mechanisms should be established to capture insights from employees. This iterative approach to process improvement should be rooted in feedback. It will ensure that the ETIM model remains effective and relevant.

7. Stay Updated

ETIM standards are evolving, and so should your data management. Engaging with the broader ETIM community provides insights into emerging best practices. A proactive stance in updating classifications will keep your data up-to-date.

To keep up with updates, you should visit the ETIM international main page. Be sure to check the page of your local ETIM provider as well. Being aware of the changes to the standard will allow you to faster adaptability. The updates might also let you know about upcoming trends in your industry.

8. Review and Report

Periodic assessments are the compass guiding ETIM adoption. Companies should measure outcomes against the pre-defined objectives. Companies then can gauge the success of their ETIM integration. Sharing these victories, both big and small, can foster a culture of continuous improvement.

Interested in learning more about ETIM benefits and adoption? Ready to unlock a world of efficiency?

Reach to our expert today.# Challenges in implementation

Implementing ETIM in your organization might be a great game-changer. But as with any other implementation, you must be aware of the potential issues. Addressing those challenges before the implementation starts will increase the chance of success. Here’s a list of the most common challenges you will come across.

Employee Resistance to Change

Employee resistance to adopting a new system like ETIM. This issue may happen due to unfamiliarity or about understanding new concepts.

Integration

Integrating ETIM can pose technical challenges. Managing that will require a knowledgeable team and a lot of integration efforts.

Data Migration

Transferring existing data into the new standardized format can be a cumbersome process. It might require cleaning up the already existing data.

Dedicated Training

Ensuring that employees are trained to use ETIM can be time-consuming. It might require initial investment in training resources and time for workshops.

Customization vs. Standardization Balance

Finding a balance in customizing ETIM to suit industry-specific needs is hard. Doing so while maintaining its standardized framework can be a challenge.

Continuous Updates:

As ETIM standards evolve, your company will need to stay updated. It requires regular revisions of your product data.

Time Commitment

The initial setup, classification, and migration can be time-consuming.

# Conclusion

As you can see, ETIM is a significant step forward in simplifying the maintenance of product data in your company. Implementation of ETIM will give a great framework for structuring your product data. As a result, it will improve your data quality and allow for easier communication between different stakeholders. Those benefits, combined with faster adaptability, will allow you to save both time and money.

Ask us any question

We will respond within 8 hours and guide you in the right direction.

Your data is safe with us. We will not share your email with anyone, and we will use it only to contact you regarding your inquiry.